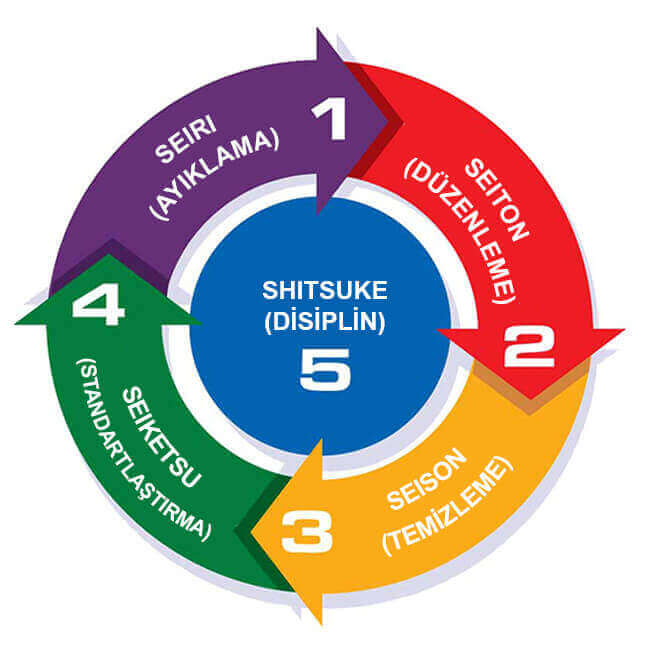

Our company is using 5S Methodology in order to create and sustain a quality work environment.

1- Take away the unnecessary parts, and equipment from the work place.

2- Organise often used parts and equipment in order to find them easily.

3- Get rid of the dirtiness caused by the workplace and machines.

4- Standartize these 3 steps.

5- Make sure 4 steps are performed periodically.

5S Methodology is also known as 6S Methodology. 6th S stands for Safety.

Atıl Kalıp Makina was inspected by the Ministry of Labor for Health and Safety at Work, which resulted in %100 positive.